Aluminum Stall Construction Advice

Horse Stall: an enclosure for a horse.

“The definition is simple, but choosing the best materials for your stalls requires planning and research.”

Jeff Covel

ARC Integrated Systems

Let’s start with the wood. You can choose from ordinary lumberyard boards (known as #2 SPF), southern yellow pine, or hardwood. 2×6 boards (typically 5.5” wide) should be the smallest size used to maintain adequate strength. Hardwood is the strongest choice with 2 caveats: be sure it’s adequately dried or you’ll get shrinkage and open gaps between the boards — a sure invitation for cribbing, and if your stall hardware is made to accept standard lumber, be sure the hardwood is cut to 1.5” thick. Southern yellow pine is stronger than SPF, but lumberyard SPF remains the most widely used because it’s readily available, moderate in price, and is strong enough for most installations. The final decision is whether to use tongue & groove boards. T&G does a great job of locking the boards together, but there are 2 extra costs to using it: The wood is considerably more expensive, and the T&G system makes the boards a little narrower, so you need more boards in the installation. If you don’t want to opt for the more costly T&G you can “tie” your boards together with bracing — wood or metal, or you can use several fastening methods between the boards.

If you have stalls in a row, you have to decide if you want solid wood between the stalls or grills like those on the stall fronts. Solid wood is strong, private and less expensive. Grilled separation walls allow for socialization and enhanced airflow. Some innovative stall designers are now using combination walls — part grilled and part solid. The solid section can offer privacy, especially when feeding, and the grilled section can offer opportunities for socialization and air flow.

Next choose your stall hardware. The most basic decision is the gap between bars. Equine vets say the maximum safe bar gap is 2¾”. An adult hoof can fit between larger gaps. The next decision is construction: welded together frames or metal framework that is pre-drilled and assembles on site. Welded frames are a little easier to assemble, but they are more expensive both to make and to ship. Stall systems that you assemble have the advantage of being very easy to modify if the barn posts are not in standard locations. These systems also allow easier repair in the future.

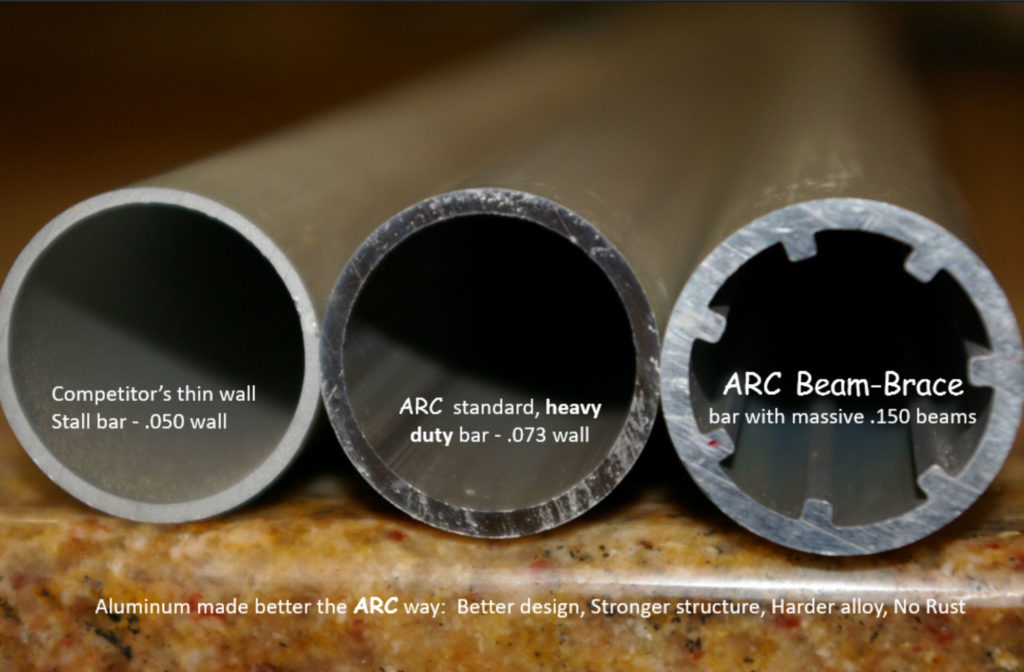

Finally choose between steel and aluminum. Steel is a stronger metal, but no matter what it’s coated with, it eventually rusts. Aluminum stays new looking indefinitely, but you must be sure that aluminum stalls are heavy enough to withstand the normal stresses associated with stall use. (Ask your supplier about wall thickness and alloy.) ARC stalls use a harder, more exotic alloy that blends small quantities of magnesium and tungsten with the aluminum for a superior product. ARC stall components also have thicker walls than competitive products for strong, long-lasting performance. Here’s ARC Stall feedback from Dr. Rhonda Herr, DVM, a vet in Harrisonburg VA about her own barn:

“As you know, I did a lot of research before deciding on your stall products. I have seen many horse injuries over the years caused by unsafe environmental conditions. I even had one of my own horses get a back leg hung up between the bars of a stall we had constructed from another company. I did not think there was any way a horse could get a hoof between those bars, but that mare did, and it ended her career. The spacing of the bars in your stall grills was a major deciding factor in my decision to buy ARC stalls. The stalls we constructed 3 years ago still look new today. The finish does not rust or dull or start to look old. We are building more stalls in a new barn and would never consider using anything but ARC stalls! Thank you for making a product that is safe, functional and beautiful.”

Dr. Rhonda Herr, DVM

Vet in Harrisonburg VA

ARC stalls are heavy-weight aluminum construction with 2.62” bar gaps. (3” to 4” gaps are common in some stalls, so be careful.) The ARC system meets all requirements for strength, longevity, and flexibility. ARC stalls offer a choice between heavy-duty 1” bars with a .073, commercial-duty bars with a .090 wall, and super-duty bars with a .125 wall. Compared these to competitor’s .050 bar and the quality is obvious. You can see the thicker aluminum by looking at an end view of the bars. What you can’t see is the aluminum alloy. ARC bars use a harder alloy that blends small amounts of tungsten and magnesium with the aluminum. This special alloy blend creates an aluminum extrusion that remains rust free but is significantly harder than more common aluminum blends. The tracks and door sides are also much heavier construction than competing aluminum products. Add the spring-back safety latch and the moderate price point, and the ARC system may well be the best stall value in America.